Sleeve Ideal For Copper Sleeve Ideal For Copper

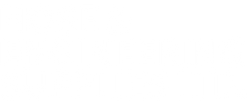

TITON Compression Fittings are designed to comply with established industry standards.This economical fitting is available in a wide range of...

TITON Compression Fittings are designed to comply with established industry standards.

This economical fitting is available in a wide range of off-the-shelf sizes and styles. They

are manufactured from high quality DZR brass alloy.

ADVANTAGES

Simple to assemble. No soldering, flaring or deburring is necessary. Suitable for use in a

wide variety of applications.

APPLICATIONS

May be used with copper, aluminium, brass, and plastic tubing. Use with steel tubing is

not recommended. Installation should be where low to medium pressures are

encountered, and modest tube vibration/movement is involved. Suitable for hazardous

liquids, oils, and fuel. Not recommended for use with gas

WORKING PRESSURES

Generally, working pressure is dependant upon the type of tubing used and not the fitting.

Consequently the table shown below should be used as a guide only.

ASSEMBLY

I. Slide nut then sleeve onto tube ensuring threaded end of nut is facing the sleeve.

II. If using a plastic tube, push a 261 Insert into tube to prevent tube from collapsing.

III. Insert the tube into the fitting until the tube has bottomed onto the fitting shoulder.

IV. Screw nut onto the fitting and tighten "hand tight". Using the table below, follow the number of additional wrench turns.

TITON Compression Fittings are designed to comply with established industry standards.

This economical fitting is available in a wide range of off-the-shelf sizes and styles. They

are manufactured from high quality DZR brass alloy.

ADVANTAGES

Simple to assemble. No soldering, flaring or deburring is necessary. Suitable for use in a

wide variety of applications.

APPLICATIONS

May be used with copper, aluminium, brass, and plastic tubing. Use with steel tubing is

not recommended. Installation should be where low to medium pressures are

encountered, and modest tube vibration/movement is involved. Suitable for hazardous

liquids, oils, and fuel. Not recommended for use with gas

WORKING PRESSURES

Generally, working pressure is dependant upon the type of tubing used and not the fitting.

Consequently the table shown below should be used as a guide only.

ASSEMBLY

I. Slide nut then sleeve onto tube ensuring threaded end of nut is facing the sleeve.

II. If using a plastic tube, push a 261 Insert into tube to prevent tube from collapsing.

III. Insert the tube into the fitting until the tube has bottomed onto the fitting shoulder.

IV. Screw nut onto the fitting and tighten "hand tight". Using the table below, follow the number of additional wrench turns.